PHOENICS for Electrolytic SmelTER

ESTER

For further details, please

Contact Sales

Thank you for your interest in our products and services.

if you would like to speak to a Sales Representative about ESTER, please fill out the following form:

New features to Ester User Interface

The ESTER user interface has been extensively upgraded to include:

- Cathode and collector bar configurations below metal pad

- Anode stubs, rods and bus bars above electrolyte layer

- Additional post-processing output, including:

- Interface height surface o Interface height map

- Voltage & current monitoring files

- Macros to create vectors from currents, magnetic fields and Lorentz Forces

Multi-anode electrolytic smelters simulation tool

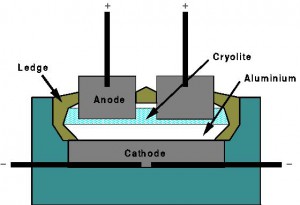

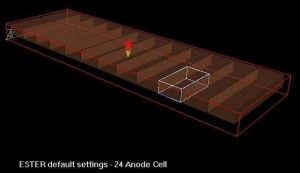

ESTER (Electrolytic SmelTER) is a special-purpose adaptation of the general- purpose fluid flow and heat transfer code PHOENICS, developed specifically for the simulation of multi-anode electrolytic smelters of the Hall-cell type. It uses a variant of the standard PHOENICS pre- and post-processors for data input and graphical display.

Features of ESTER

ESTER enables the user fully to represent the smelter in 3-D taking into account all the major features of its design:

- any number of anodes in any arrangement

- the frozen electrolyte around the edge of the cell

- distortion of the metal-electrolyte interface due to pressure differences and due to vertical Lorentz Forces

- erosion of the anode undersides to follow the shape of the metal-electrolyte interface and

- current generation due to the motion of the metal - the induced current

- three components of metal velocity

- three components of electrolyte velocity

- the pressure

- the gas fraction under the anodes, and the inter-anode gaps; and

- the electric potential distribution.

Based on these, it deduces:

- the height of the metal-electrolyte interface, and the height of the electrolyte free surface; and

- the electric current distribution, and the induced currents. These, together with given magnetic fields, are used to compute the Lorentz forces which drive the flow.

ESTER extensions

- ESTER has further extensions, to include:

- thermal calculations, including the formation of freeze;

- calculation of aluminum oxide concentration in the electrolyte;

- interface to magnetic field calculation programs;

- interface to programs which can update the anode potentials and the cathode currents.